Co-Injection Analysis Services

Co-Injection provides an invaluable tool for simulating the process where a skin material is injected first, followed by the injection of a different core material. Co-Injection is the ideal process for using recycled materials or achieving specialized cosmetic and structural objectives.

Results of a Co-Injection study can determine the following:

The pattern of two co-injected materials to aid in part design and gate placement

The extent of penetration of the core material in relation to the skin material

The injection pressure and clamp force requirements for molding machine selection

The best transition point for switching from skin-material to core-material injection

Optimal inlet melt temperatures for skin and core materials

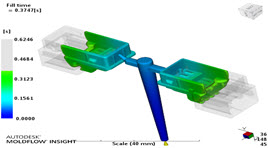

Thickness fraction of polymer B shows what percentage of the wall is occupied by the second polymer for co-injection. This plot shows the penetration about halfway through the filling process.

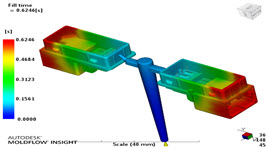

Thickness fraction of polymer B shown at the end of injecting the second polymer.

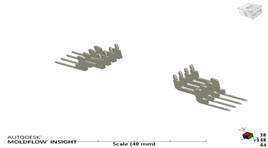

Thickness fraction of polymer B shown at the end of injecting the first polymer for the second time.