Flow & Pack

MOLD BUILDING

Flow analysis is the first stage of the molding simulation process. Flow calculates the melt front advancement that grows through the part from the injection location, and continues until the switch-over point to packing. Flow analysis provides the ability to simulate, identify, and optimize the process to avoid molding uncertainty or resolve an existing injection molding problem.

Flow analysis evaluates or determines the following:

Uniformity of fill

Number of gates

Gate size and location

Weld line location

Air entrapment

Pressure & temperature

Shear rate, shear stress

Part designs

Processing conditions

Hot runner sizing

Sequential valve gating

Runner balancing

Packing Analysis

Filling analysis is only the first stage in a series of cost saving analyses. Packing analysis builds on the results of the filling analysis by extending the first stage of the injection molding process into the packing phase. This second stage fills the non-filled portion of the mold with additional material to compensate for the loss in volume as the material shrinks. The part is then held under pressure while it solidifies.

Packing analysis evaluates or determines the following:

Gate freeze time

Packing pressure profile

Volumetric shrinkage

Sink location

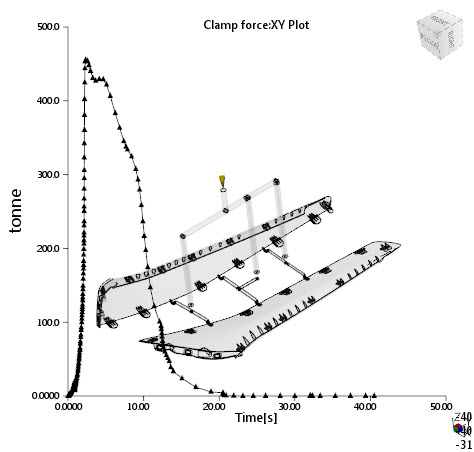

Clamp tonnage/machine sizing