Injection Compression Molding Analysis

Injection-Compression molding is a process that combines the techniques of injection molding and compression molding. The compression phase can be programmed to begin before, during, or after polymer injection. Analysis simulates all major process control schemes for a total evaluation of candidate materials, part design, mold design, and process conditions.

Results of an Injection Compression study can determine the following:

The flow front pattern from both material injection and compression due to mold closing

Molding feasibility of extremely thin-wall parts

Injection pressure and clamp force requirements for proper molding machine selection

Gate placement to minimize injection pressure and clamp force

The initial mold open distance prior to the compression stage

The time to begin compression of the mold cavities

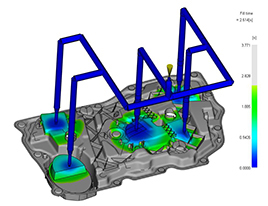

Shown above is the extent of melt front advancement for the instant at which the process switches from injection to compression.

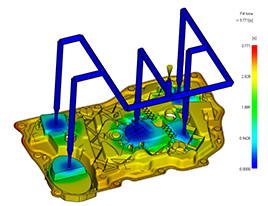

Shown here is the melt front advancement at the end of compression, indicating that the mold filled completely.